100 mtrs Reel ‘XP PREMIUM’ fire resistant cable 2 core, 1.5mm square solid core, Red, LPCB approved

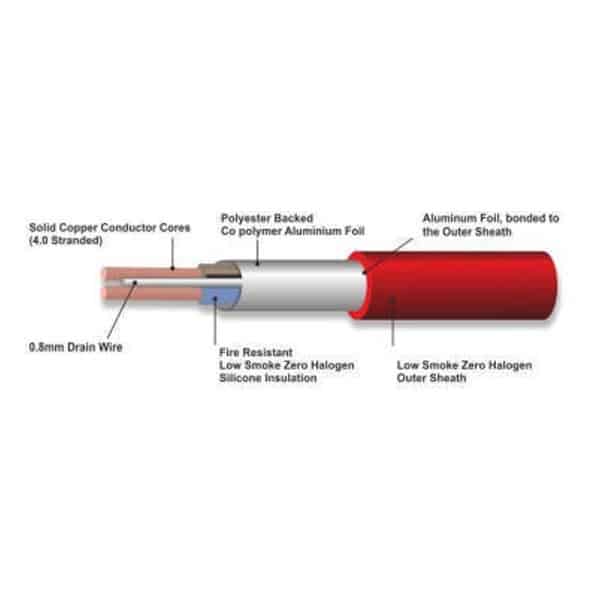

• Made of 2 solid copper conductor cores 1.5mm² each with 0.8mm drain wire, the cable construction is shown in the photo below

• All Context Plus fire resistant cables are approved & certified by LPCB to meet current British and European fire test standards plus the additional life safety requirements provided by Low Smoke & Zero Halogen emission levels.

• Twisted during manufacture to provide the highest level of data protection, ideal for long cable runs and analogue addressable fire systems

• Easy to Install and Superb Working Flexibility

• Up to 12 Twists per metre for Data Protection

• Red and White Outer Sheaths Available

• Supplied in 100m length on a solid plastic Reel. Available also in 500m length.

• Conductors made of ETP1 High grade copper

100m and 500m Reels are available.

All the Context Plus XP Premium fire-resistant cables are certified and approved to the following British and European Standards:

| Ref | Description |

|---|---|

| BS 6387 C | To comply with this standard the cable must retain continuity for 180 minutes under fire condition at 950 degrees C |

| BS 6387 W | To comply with this standard the cable must retain continuity for 30 minutes under fire condition at 650 degrees C with water spray applied during the final 15 minutes |

| BS 6387 Z | To comply with this standard the cable must retain continuity for 15 minutes under fire condition at 950 degrees C with a mechanical shock applied every 30 seconds during the full 15 minutes test |

| BS EN 50200 PH30 | To comply with this standard a cable must retain continuity for 30 minutes under fire condition at 830 degrees C with a mechanical shock applied every 5 minutes during the full 30 minutes test |

| BS EN 60332 | To comply with this Flame Retardancy Standard a cable must self-extinguish leaving the upper cable sheath unaffected when a flame of 1kw of caloric power is applied for 30 seconds to it. This then demonstrates that the cable does not propagate fire. |

| BS EN 60754-1:2014 | To comply with this Zero Halogen standard a cable must have an Emission of less than 0.5% of corrosive & acid gas when under fire condition |

| EN 61034-2:2005:+A1:2013 | To comply with this Low Smoke standard a cable must be Meeting at least 60% for residual light transmission when under fire condition |

| BS EN 50200 PH60 | To comply with a cable must retain continuity for 60 minutes under fire condition at 830 degrees C with a mechanical shock applied every 5 minutes during the full 60 minutes test |

| BS EN 50200 PH120 | To comply with a cable must retain continuity for 120 minutes under fire condition at 830 degrees C with a mechanical shock applied every 5 minutes during the full 120 minutes test |

| BS EN 50200 + Annex E 30 mins | To comply with this standard the cable must retain continuity for 30 Minutes under fire conditions at 830 degrees C with a mechanical shock applied every 5 minutes during the full 30 minutes and for final 15 minutes water spray is applied |