100 mtrs Reel ‘HP HIGH PERFORMANCE’ fire resistant cable 2 core, 1.5mm sq solid core, Red, meets BS5839 Pt1 2002 26.2d – 26.2d. LPCB approved

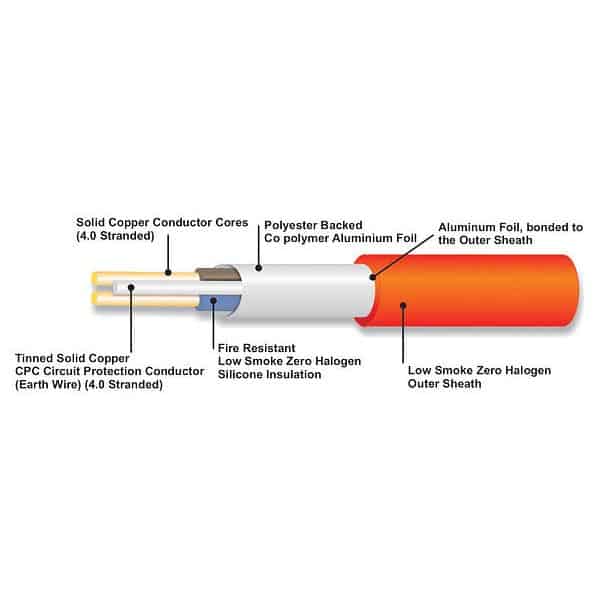

- Made of 2 solid copper conductor cores 5mm² each with an additional Earth core called a CPC Circuit Protection Core, the cable construction is shown in the photo below

- All Context Plus fire resistant cables are approved & certified by LPCB to meet current British and European fire test standards plus the additional life safety requirements provided by Low Smoke & Zero Halogen emission levels.

- Twisted during manufacture to provide the highest level of data protection, ideal for long cable runs and analogue addressable fire systems

- Easy to Install and Superb Working Flexibility

- Up to 12 Twists per metre for Data Protection

- Red and White Outer Sheaths Available

- Supplied in 100m length on a solid plastic Reel. Available also in 500m length.

- Conductors made of ETP1 High grade copper

100m and 500m Reels are available.

All the Context Plus HP High Performance fire-resistant cables are certified and approved to the following British and European Standards:

| Ref | Description |

|---|---|

| BS 6387 C | To comply with this standard the cable must retain continuity for 180 minutes under fire condition at 950 degrees C |

| BS 6387 W | To comply with this standard the cable must retain continuity for 30 minutes under fire condition at 650 degrees C with water spray applied during the final 15 minutes |

| BS 6387 Z | To comply with this standard the cable must retain continuity for 15 minutes under fire condition at 950 degrees C with a mechanical shock applied every 30 seconds during the full 15 minutes test |

| BS EN 50200 PH30 | To comply with this standard a cable must retain continuity for 30 minutes under fire condition at 830 degrees C with a mechanical shock applied every 5 minutes during the full 30 minutes test |

| BS EN 60332 | To comply with this Flame Retardancy Standard a cable must self-extinguish leaving the upper cable sheath unaffected when a flame of 1kw of caloric power is applied for 30 seconds to it. This then demonstrates that the cable does not propagate fire. |

| BS EN 60754-1:2014 | To comply with this Zero Halogen standard a cable must have an Emission of less than 0.5% of corrosive & acid gas when under fire condition |

| EN 61034-2:2005:+A1:2013 | To comply with this Low Smoke standard a cable must be Meeting at least 60% for residual light transmission when under fire condition |

| BS EN 50200 PH60 | To comply with a cable must retain continuity for 60 minutes under fire condition at 830 degrees C with a mechanical shock applied every 5 minutes during the full 60 minutes test |

| BS EN 50200 PH120 | To comply with a cable must retain continuity for 120 minutes under fire condition at 830 degrees C with a mechanical shock applied every 5 minutes during the full 120 minutes test |

| BS EN 50200 + Annex E 30 mins | To comply with this standard the cable must retain continuity for 30 Minutes under fire conditions at 830 degrees C with a mechanical shock applied every 5 minutes during the full 30 minutes and for final 15 minutes water spray is applied |

| BS 7629-1 | To comply with this standard the fire cable must be 300/500 Volts rated and must have low emission of smoke and corrosive (Halogen) gases when affected by fire. |

| BS 8519:2010 Category 1 | To meet this standard a cable must demonstrate that its level of circuit integrity (Fire Survival of 30 minutes) is not compromised by other components of the whole electrical distribution system, including cable glands, terminations, joints and cable support systems |

| BS 5839-1:2013 Clause 26.2d 'Standard 60' Fire Cable | To comply with this standard the fire must be tested to comply with all the standards described above: BS EN 50200: 2006 + Annex E 30 mins , BS EN 50200: 2006 PH30, BS 7629-1:2008, BS 6387: 1994 C, W & Z, BS EN 50267-2-1:1999, BS EN 61034-2:2005 |